Feature

- We have developed a wire cutter that's easy to install, since an I/O connection with the robots in use is unnecessary.

- Cutting errors are eliminated by sliding one cutter over the other to make each cut, and the 10-sided blades provide excellent durability.

- It contributes to improve weld quality by keeping wire lengths constant without stopping production lines.

Step 1

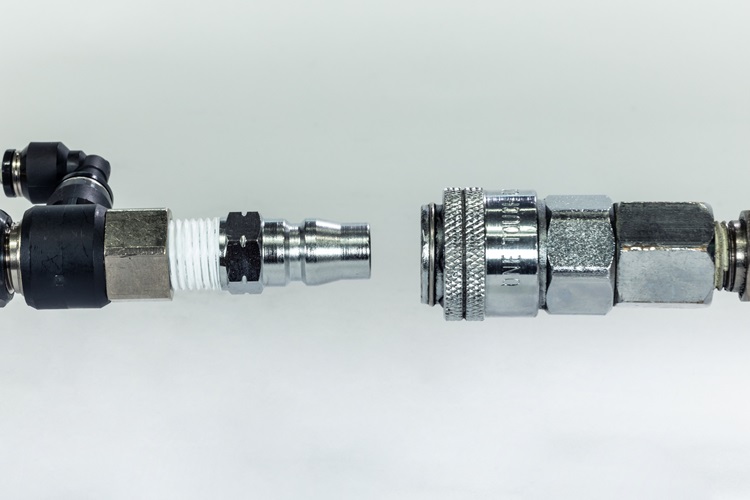

To install the device, the only input required is a pneumatic hose.

Communication with the robots in use is unnecessary.

Step 2

The nozzle is inserted into the holder, and the wire is extended.

Step 3

When the nozzle is pressed down on the device, the wire is cut at the predetermined length.

As one cutting blade slides over the other to make each cut, there are no cutting errors.

In addition, since the circular cutters can be partially rotated up to 10 times, they are extremely long-lasting.

As one cutting blade slides over the other to make each cut, there are no cutting errors.

In addition, since the circular cutters can be partially rotated up to 10 times, they are extremely long-lasting.

Step 4

The nozzle is pulled back up and cutting is complete.