Feature

- We have created a torch cleaner that does not require an I/O connection

- with the robots in use, making it very easy to install.

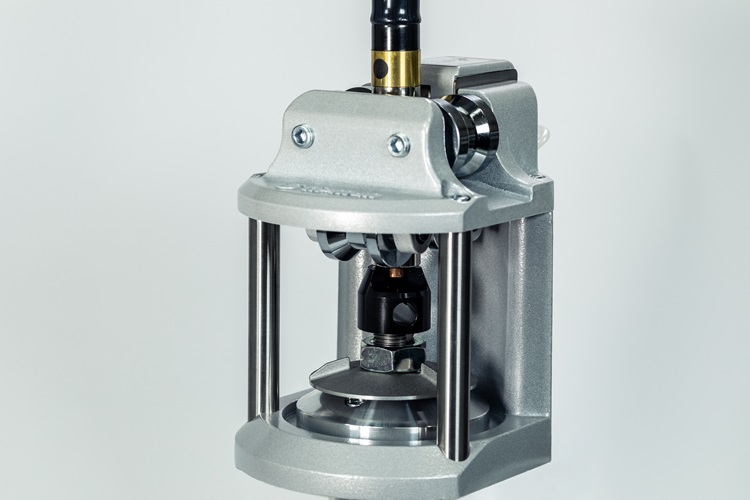

- By developing an original clamp system (4WD) that minimizes

- vibrations even when the reamer's rotation speed is high, robots' shock

- sensors will not react when their nozzles are being cleaned.

- In addition to shortening cleaning time, it always cleans nozzles at a

- consistent quality without stopping production lines.

Step 1

During installation, the only input required is a pneumatic hose.

Communication with the robots in use is unnecessary.

Step 2

The welding nozzle is inserted into the clamp rollers.

Step 3

When the nozzle presses down on the switch, the reamer starts rotating at high speed and cleaning begins.

The torch does not vibrate or move while it is being cleaned, as it is held securely in place with an originally-developed clamp system (4WD).

The torch does not vibrate or move while it is being cleaned, as it is held securely in place with an originally-developed clamp system (4WD).

Step 4

Spatter that has been scraped off the nozzle can be crushed and collected together in one place without scattering.

Step 5

The nozzle is pulled back up and cleaning is complete.