Feature

- We have developed a spatter deposition prevention spray system that is very easy to install, as it does not require an I/O connection with the robots in use.

- The amount of spray can be adjusted with a valve, and further fine-tuning is possible by adjusting the amount of time the nozzle is pressed down.

- The excess liquid is collected, which keeps it from contaminating the workplace.

- It contributes to improve weld quality by maintaining nozzles at a consistent quality at all times without stopping production lines.

Step 1

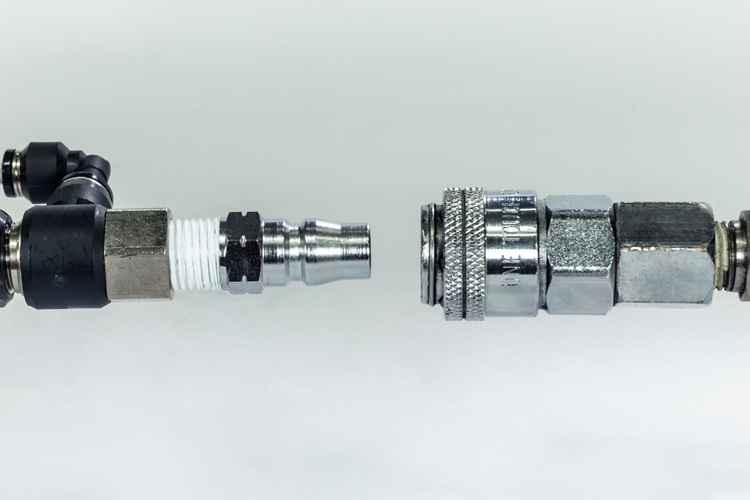

To install it, the only input required is a pneumatic hose.

Communication with the robots in use is unnecessary.

Step 2

The welding wire is retracted, and the nozzle is inserted into the holder.

Step 3

The nozzle is pressed down on the device, and it is sprayed with an anti-spatter liquid. Spray is evenly applied to the inside of the nozzle.

Step 4

The amount of spray can be adjusted to prevent the anti-spatter liquid from going to waste. The excess liquid can also be recovered and reused.

Step 5

The nozzle is pulled back up and spraying is complete.