Feature

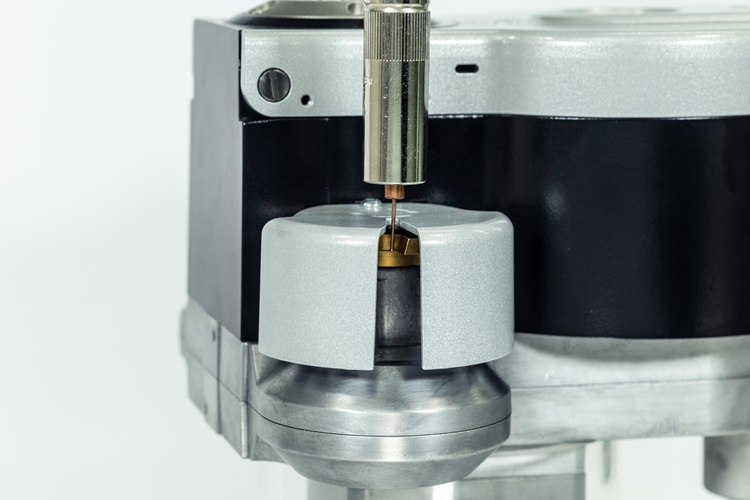

- The Auto Contact Tip Changer makes it possible to automate the.

- time-consuming process of contact tip replacement.

- As tips can be replaced without having to stop production lines, robot

- operation rates can be increased significantly.

- It is compatible with a variety of contact tips, and the mechanized

- process tightens the tips to a specified torque. By ensuring that all tips

- are replaced regularly without fail, it also helps to further increase the

- stability of product quality.

Step 1

The welding wire is cut and pulled into the torch body.

Step 2

The nozzle is removed.

Step 3

The tip body is cleaned.

Step 4

A new contact tip is prepared for loading, then the old contact tip is removed. Removed contact tips are automatically discharged and can be collected in a waste disposal box.

Step 5

A new contact tip is inserted and screwed on.

The rotation automatically stops when the specified torque is reached.

Up to 10 contact tips can be loaded at a time and, since there is only one mounting position,

it is also easy to train engineers on how to use it.

The rotation automatically stops when the specified torque is reached.

Up to 10 contact tips can be loaded at a time and, since there is only one mounting position,

it is also easy to train engineers on how to use it.

Step 6

Lastly, the nozzle is reattached. Like the contact tip, the rotation stops automatically once the specified torque is reached.

Since everything is automated, there is no need to worry about over or under tightening.

Once the installation of the tip and nozzle are confirmed, the robot is returned to the production line.